Engineering and Design: The Science Behind Strength

They are the critical element that directly interacts with the material, withstanding the greatest impacts and constant abrasion.

Our commitment is to ensure that each tooth maximizes the lifespan of your equipment and optimizes productivity, from the mine to the construction site.

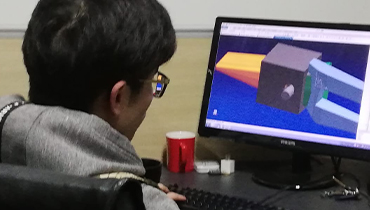

The life cycle of a Petrax tooth begins on the design table. Our engineers use state-of-the-art 3D modeling software to:

- Optimize geometry: We design shapes that allow for superior penetration, reduce the required force, and facilitate material flow, minimizing buildup.

- Simulate stresses: We perform Finite Element Analysis (FEA) to predict and reinforce the points that will withstand the greatest stress and impact, ensuring optimal structural strength.

- Ensure compatibility: Our designs are perfectly adapted to the leading brands and models of excavation and loading equipment.

Material Selection: Alloys for the Highest Demands

Not all steels are created equal. We select the highest quality steel alloys, with specific heat treatments for each application:

Manganese Steels: Strength, Durability, and Industrial Applications Worldwide.

Medium and High Alloy Steels: Ideal for combining hardness and toughness.

Controlled Heat Treatment: Precise quenching and tempering processes

More than a Teeth, a Productivity Partner

Controls at every stage: We inspect everything from raw materials to the final product.

Precision Manufacturing: Where Design Comes to Life

We use robust and controlled manufacturing processes to transform raw steel into a high-performance.

Quality Control and Certifications: Our Guarantee of Reliability

Quality is non-negotiable. All our processes comply with the strictest international standards.

Packaging and Logistics: We Protect Your Investment

We use individual packaging and heavy-duty cardboard boxes to prevent damage during and storage.

A quality tooth must be installed correctly to perform at its best.

Installation and Operation: Maximizing Their Useful Life

Our technical team offers guidance on the correct installation procedure and torque for retaining bolts. Teeth life also depends on its use. Operating the equipment within its parameters and under the right conditions significantly extends the component's life.

Premium Wear Parts for Leading

Equipment Brands

We supply high-performance wear parts engineered for the world’s most trusted construction and earthmoving machinery—ensuring durability, precision, and optimal fit across a wide range of OEMs.

All trademarks and logos are the property of their respective owners and are used for identification purposes only

Please contact us for a free quotation and tell us more about your project

Thank you for your interest in requesting a work estimate, please fill out the form and we will get back to you shortly.

(+1) 786 536 2557